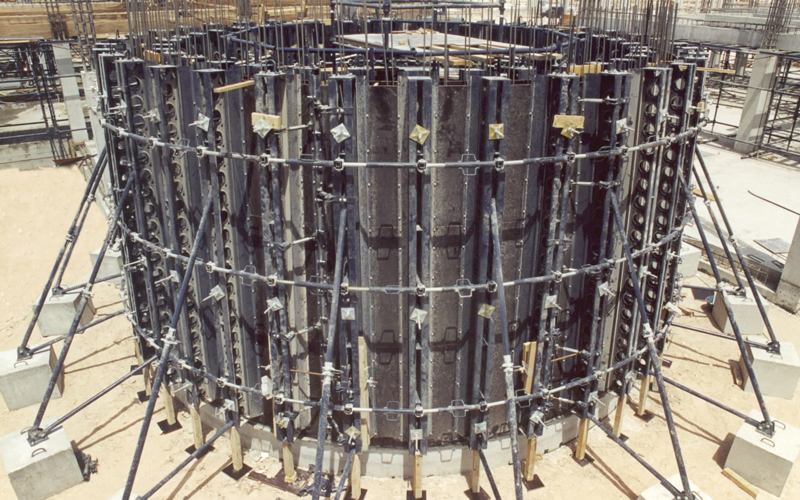

BENEFITS

• Depending on the technical specifications and features of the project, custom-made formwork can be designed and implemented by the SCAFFCO.

• Custom Made Formwork provides high dimensional accuracy

• Perfect surface quality is achieved with custom made formwork

• Easy assembly and disassembly

• Integrated safety and working platforms

• Ultimate engineering to ensure high precision calculations and quality of the custom made formwork product

• SCAFFCO provides complete technical support with economical custom made formwork solutions at site

• Finish: galvanized or painted finish can be offered

• Standard health and safety: Guard rails and Edge protection is normally fixed after or during the assembly of the system units

• Sustainability: The formwork system is reusable with little waste

• Increased speed and time efficiency on-site.

• Simplicity of assembly and disassembly: reduces the requirement for skilled labor

• All system components are manufactured in SCAFFCO premises.

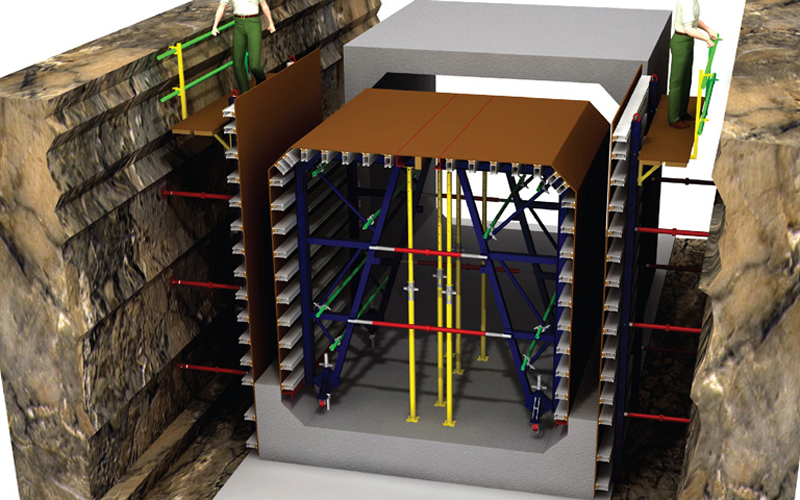

TUNNEL FORMWORK : Custom Made for Project Success

Tunnel Formwork with Standard Components provides unique construction advantages to expedite project completion and profitability.

Tunnel form is a formwork system that allows construction of cellular walls and slabs in one operation on a daily cycle. It combines the speed, quality and accuracy of offsite production with the flexibility and economy of on-site construction and is recognized as a modern method of construction. The result is a cellular reinforced concrete structure, the surfaces of which are of sufficiently high quality to require only minimal finishing for direct decoration.

The benefits of using custom made tunnel formwork:

• Its modular system design provides dimensional accuracy and versatility.

• Lower concrete forming costs, improves labor productivity and requires less finishing.

• It produces a monolithic concrete structure that reduces re-shoring requirements.

• Reduced masonry, framing and drywall is needed for interior walls.

• Faster completion times to reduce interim financing and accelerate project revenues.

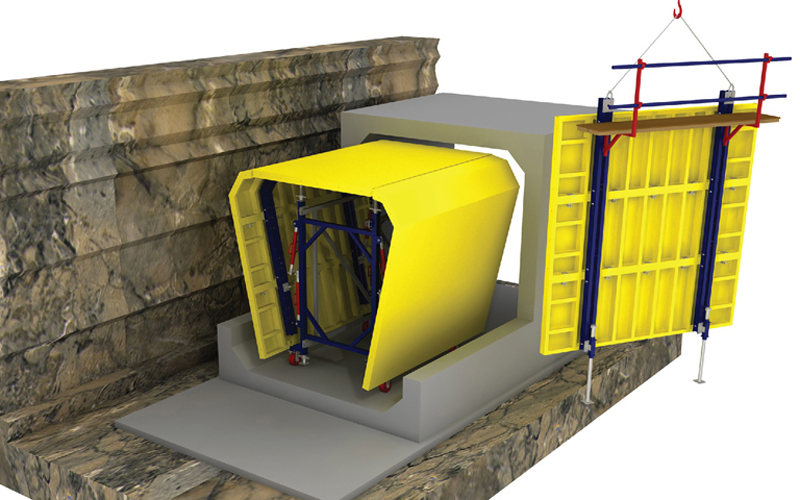

CULVERT FORMWORK : Quick Solution for Instant Bridging

Box culverts are an ideal solution to rapidly create pathways for pedestrian, fauna and stock crossings under road and rail applications.

Using culvert formwork is recognized as a modern method of construction, culvert form simplifies the whole construction process by enabling a smooth and fast operation that can result in frame costs being reduced by large amounts. It provides frame program time savings of up to 50%.

During the construction process, a structural culvert is created by pouring concrete into custom-made steel formwork or formwork with standard elements to make the top slab and walls in one massive process. Every 24 hours, the formwork is moved so that another pouring cycle can be accomplished. A strong, monolithic structure is thus constructed.

The box culvert formwork customized with standard formwork elements is highly adjustable, highly flexible and still reusable for other forming purposes.

• Versatile : Complete system made to meet the needs of contractors.

• Easy to Use : Quick assembly & fixing.

• Proven Design : Fabricated for tough working conditions.