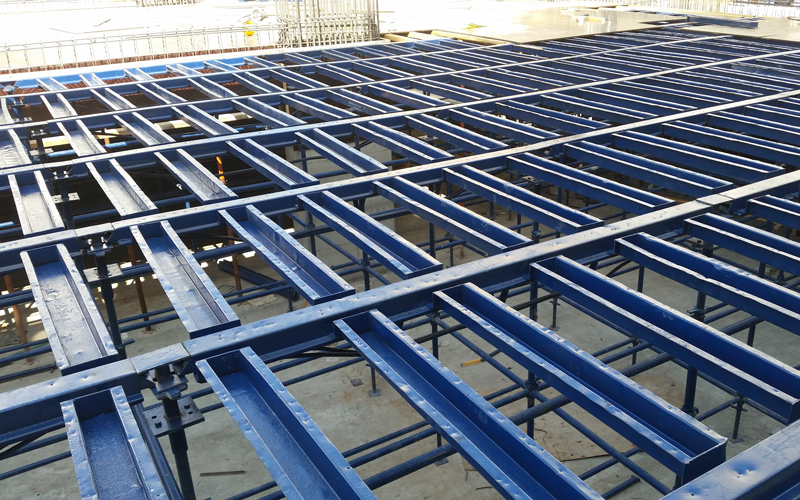

SCAFFLOCK SYSTEM

FEATURES OVERVIEW

• High leg loads carrying capacity : up to 40 KN per vertical

• Unique leg node point : accepts 4 ledgers, four horizontals can be fastened at one time with firm clamping action of top cup making the joint rigid

• Systemised bracing

• The Scafflock System incorporates components for access cantilever and internal or external drop beams

• Drop Forged Parts

• Early Striking Option

• Multiple decking options can be used efficiently : steel beams decking (infill beams and decking beams) , timber beams decking (H20, LVL, traditional timber) or Aluminium beams decking (S150, T150, T225).

• Lightweight system for access purposes

• High number of reuse cycles

• Finish options available are galvanized finish or painted finish

• Standard health and safety protection components offered

• Normally, plywood by contractor, but can be provided by SCAFFCO on request

• All system components are manufactured in SCAFFCO premises

ADVANTAGES

• Scafflock System is usable as an access or load bearing system suitable for all types of structures: commercial, residential and infrastructure.

• The adaptability of the Scafflock System to any slab thickness, height or layout makes it a well known and most commonly used system by contractors for both straight or curved structures on the construction site.

• Drop forged parts of the Scafflock System provide high durability and safety in the toughest construction environments.

• Early striking option makes the Scafflock System one the most economical systems for construction sites, due to it providing a technique for the formwork to be removed 3 to 4 days after pouring a slab, but the supporting structure of scaffolding or props remains undisturbed until the concrete is strong enough to support its own weight over its full span.

• The Scafflock System is reusable with little waste and low maintenance over many construction cycles to be a champion for sustainability in use.

• Crane time can be optimized since basic assembly of Scafflock System is possible with minimal crane use as components can be manually handled.

• No loose components in the Scafflock System allow for fast erection with simplicity in assembly, dismantling and storage. Other than improving time efficiency on site, the Scafflock System reduces the requirement for skilled labor.

• Guard rails and Edge protection is normally fixed after or during the assembly of the system units to meet with standard health and safety norms.

• Scafflock System is versatile for use in construction, shoring, access, demolition or maintenance projects of any type with a proven safety and performance record.